-

Custom Output

-

Custom Module

-

Custom Mounting Plate

-

Custom Lens

Optics & System Customization

To fully meet the unique requirements of customers in various complex application scenarios, Quanhom has meticulously developed a range of professional

customization services, covering optical design, component manufacturing, and sample or mass production. Once the project is initiated, our engineering team will

respond promptly, offering precise and highly innovative design solutions backed by extensive industry experience and cutting-edge technology.

customization services, covering optical design, component manufacturing, and sample or mass production. Once the project is initiated, our engineering team will

respond promptly, offering precise and highly innovative design solutions backed by extensive industry experience and cutting-edge technology.

-

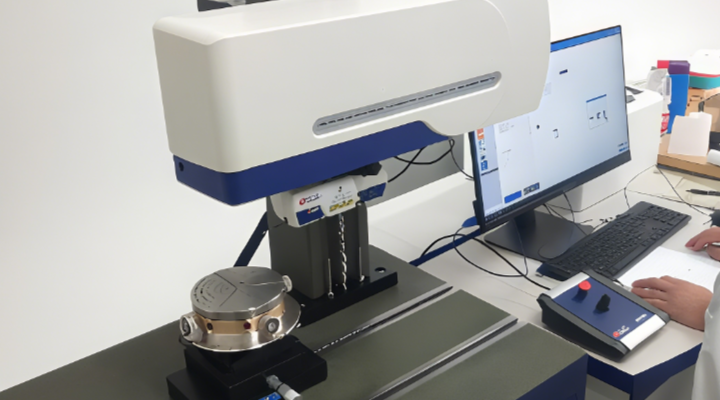

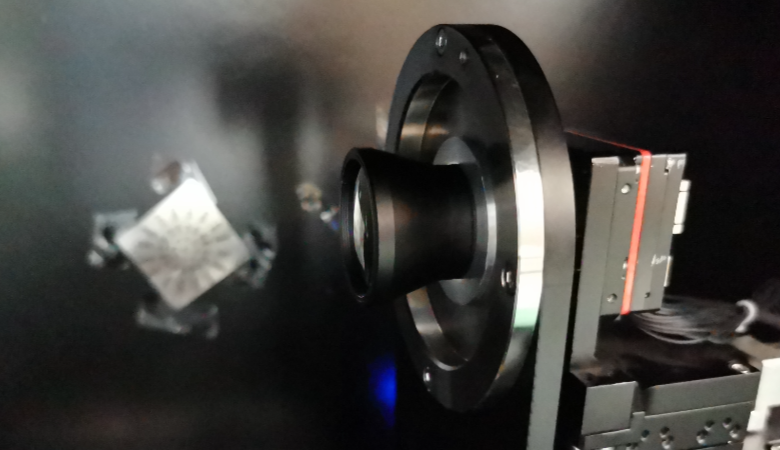

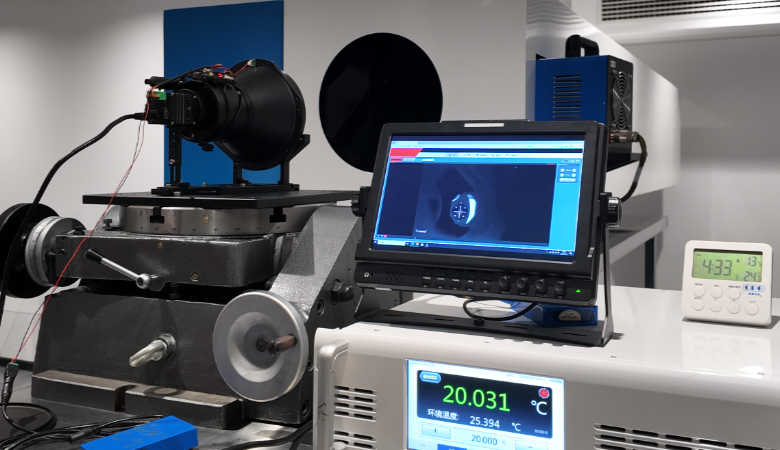

Optical Processing EquipmentDuring the production process, we utilize first-class optical processing equipment, such as:Optical Processing Equipment: Single-Point Diamond Turning (SPDT), CNC Polishing Machines, Coating MachinesMechanical Processing Equipment: CNC Cutting Machines, High-Precision Grinding MachinesWith these high-precision tools, we ensure the dimensional accuracy and surface quality of each custom component, guaranteeing stable and reliable product performance. Additionally, all products adhere to ISO 9001 and ISO 27001 quality management standards, ensuring strict control at every stage to meet global quality requirements.

-

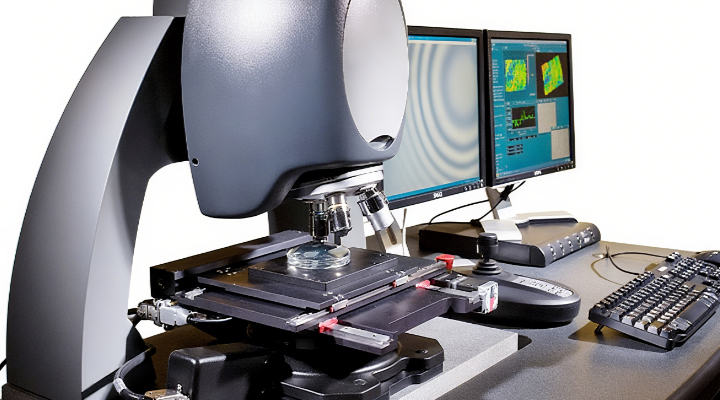

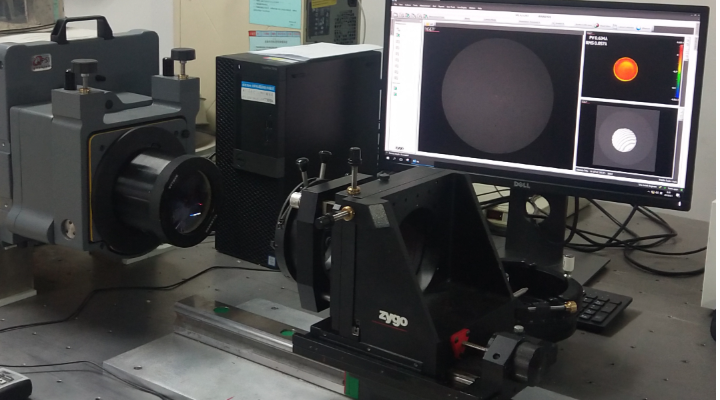

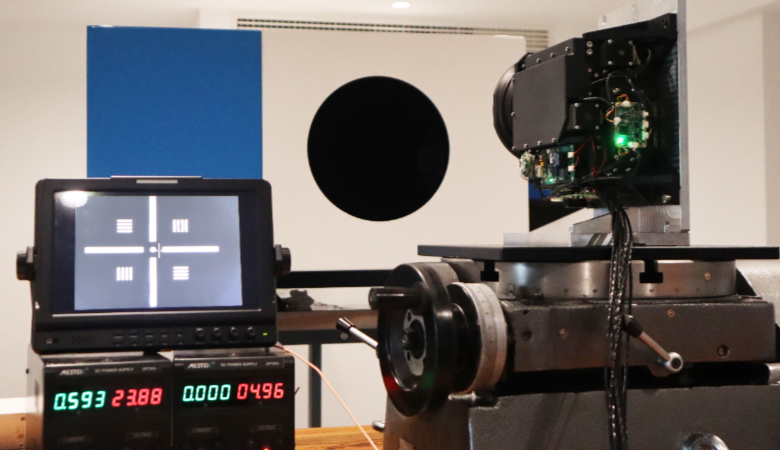

Complete Test EquipmentQuanhom also possesses comprehensive testing equipment to ensure product performance and reliability:Precision Optical Testing Equipment: Collimator, Profilometers, Interferometers, Spectrometers, SpherometersReliability Testing Equipment: High and Low Temperature Test Chamber, Vibration Testers, Waterproof Testers, GJB (National Military Standards)Whether you have specific requirements for optical performance, shape, weight, operating temperature, vibration, or compatibilty, Quanhom can provide customized solutions,

ensuring the product operates stably under IEC 60068 environmental testing standards.

Customized communication process

-

Requirement

Validate -

Scheme

Design -

Cost and

Delivery Time -

Contract

Signing -

Production &

Delivery

production process

-

01

-

02

-

03

-

04

-

05

-

06