The Principles of MWIR Imaging

1. The fundamentals of thermal infrared imaging

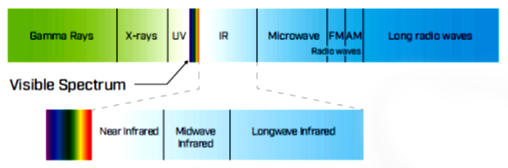

Thermal infrared imaging usually refers to MWIR imaging at 3-5 μm and LWIR imaging at 8-12 μm. In these wavebands, the focus is on the heat source, not the visible light. Thermal infrared imaging has many different applications, such as non-destructive testing, capturing over-hot spots of equipment or heat loss locations in buildings by infrared cameras, differences in temperature of local surfaces can be measured in the medical field, searching for thermal leakage points in cooling systems of nuclear power plants rapidly, safety protection and so on.

The human eye is sensitive to bands of about 0.4 to 0.7 μm and cannot see thermal energy at longer wavelengths. To record this energy, special detectors or sensors are required, and the imaging optical system must also transmit these wavelengths of light efficiently.

Most optical glass has a transmission wavelength of no more than 2.5 μm. The transmission wavelength of some special glass is up to 4.5 μm and the transmission wavelength of molten quartz is up to 4 μm. Therefore, infrared transmission materials are pivotal, but their choice is very limited, and there are other problems.

2. The characteristics of thermal infrared imaging optical system

(1) Dewar bottle assembly, cold light diaphragm, and cold shield

When thermal systems observe heat sources, most thermal systems use cryogenic refrigeration detectors to ensure that the detectors work at low temperatures for maximum sensitivity.

If these detectors can detect thermal energy other than the observed scene, the sensitivity will be reduced. In addition, if the magnitude of the energy of the non-scene varies with the field of view, you will usually see the scene image deformed.

For maximum sensitivity and to avoid image distortion, the infrared PFA is cooled at low temperatures and installed in an insulation dewar bottle assembly.

Dewar bottle is a bottle with double-layered walls and vacuum, the incoming window must transmit infrared radiation, cold finger contact with the end of the FPA to keep the FPA at low temperature. Cold finger is a mental bar made of iron or steel with high specific heat, which is surrounded by tubes and there is liquid nitrogen pumped from the tubes. This cycle allows the end of the FPA to cool down.

(2) Cold light diaphragm efficiency

If the detector can only detect or record energy from the scene, the infrared system is said to have a 100% cold light diaphragm efficiency. If the efficiency of the cold light diaphragm is 100%, the detector records both the light cone energy from the energy representing the scene and the energy from the low temperature cooling baffle. The baffle is called a cold light diaphragm, and does not have its own energy radiation. For each pixel on the FPA, the system does have 100% cold light diaphragm efficiency if only a fraction of the energy is detected, including the stereo angle of the imaging light and the thermal baffle of the cold light diaphragm.

If the detector is installed in a dewar bottle assembly that does not have 100% cold light diaphragm efficiency, the detector can observe the stereo angle representing the scene, which does not come from the scene, but from a part of the system. This part of the non-scene energy is similar to the noise in the visible optical system. If this part of the non-scene energy is "hot", the detector's sensitivity will be lower than its nominal value. However, if this part of the non-scene energy within the FPA range or during the scanning process there is an amplitude change, the image will deform, which is similar to the ghost image in traditional visible light system.